Be Flexible When Looking for Rigid Foam Insulation

The residential construction industry likes to stick with what it knows when it comes to rigid foam insulation. For BASF’s Justin DeMarco, that’s a mindset that needs to change.

It’s hard to deny the versatility that rigid foam insulation brings to residential builds. From the roof to the walls and below grade, it’s a great insulator that increases the performance and comfort of a home. Of the options available, extruded polystyrene (XPS) has been a popular option in North America for years. But, does it still hold up against current construction material innovations?

Even gold standards start to lose their luster

Breaking building habits can be hard and for Justin DeMarco, Specification and Business Development Manager at BASF, it’s no surprise that XPS continues to be a popular option.

“The preference for XPS seems to come down to a couple of factors: builders have been using it for years so there is a comfort level with the material and it’s readily available, making it easy to get. But, the main driver and probably the most obvious, is price point.”

Factors like these make XPS a simple choice but with more sophisticated builders and homeowners demanding energy efficiency paired with growing efforts to reduce the overall impact on the environment, it’s becoming clear that XPS may not be the best choice any longer.

“I think one of the biggest disadvantages is the fact that North American XPS loses its thermal resistance over time,” explains DeMarco. “It’s a pretty considerable downside to the material and future home owners are the ones paying for it with higher utility bills because they’re not getting the same thermal resistance in year five as they did in year one of owning a home insulted with it.

“On top of that, it’s important to consider the environmental impact of XPS. Despite the world shifting to low-Global Warming Potential (GWP) blowing agents, XPS in North America tends to still be extruded with greenhouse gases HFC-134a or HFC-142b. The Global Warming Potential of HFC-134a is 1,430 times more harmful to the atmosphere than carbon dioxide while HFC-142b is 2,310 times more harmful. These options are simply unsustainable.”

So what’s the alternative to XPS in North America? For BASF, it’s a spin on a material that already exists, but with some added chemistry.

What’s gold is grey

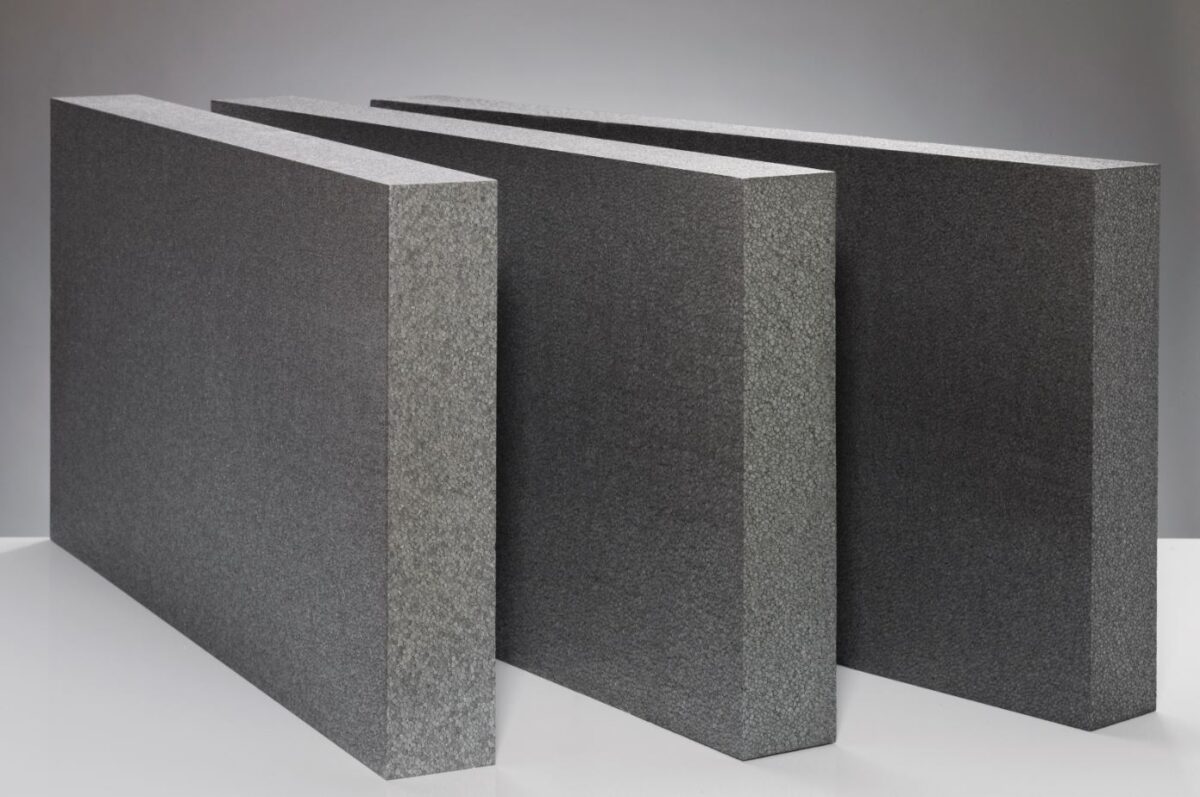

It’s important to differentiate one rigid foam insulation from the other and more often than not, manufacturers will use a specific color to create that separation. For BASF’s Neopor®, the color actually serves a higher function other than simple brand recognition.

“The grey isn’t just a color additive. It comes from the high-purity graphite that’s impregnated into the polymer matrix,” says DeMarco. “Neopor®’s graphite builds on the benefits of expanded polystyrene as it both reflects and absorbs radiant heat energy, slowing down the flow of heat much better even at lower densities.”

Graphite’s reflective properties also ensures Neopor®’s R-value does not degrade over time the way XPS does. In fact, Neopor®’s R-value increases as the temperature outside drops.

“We have customers who are offering a 50 year warranty on their insulation despite Neopor® only being around for about 20 years. Neopor® doesn’t rely on a blowing agent that off gasses to boost its R-value. That’s the kind of confidence we’re seeing in Neopor® and its ability resist the flow of heat compared to other rigid foam insulations,” says DeMarco.

With all these benefits, including its moisture management and drying potential in extreme weather, the most important factors remain: the cost benefit to the builder and the long term utility cost impact to home owners.

“It’s important for builders to build homes in a cost-effective way while still putting emphasis on building efficiently alongside consideration for the environment.

“Neopor® requires 30 per cent less raw material to produce the same thermal resistance compared to XPS. For example, Neopor® Type XI insulation at R-10 is 30 per cent less expensive than XPS Type X at R-10.

“Innovative products like Neopor really let builders see that saving money doesn’t have to come at the expense of the environment and that BASF creates chemistry for a sustainable future,” says DeMarco.

To learn more about Neopor® and how BASF can help you build for a sustainable future, follow the link.